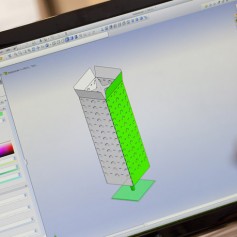

Construction

Using the program “SolidWorks”, our constructors will draft the corresponding drawing according to your specifications. The machine data needed for production will automatically be made available to all relevant programming stations by the construction department.