Consulting – Development – Planning – Construction

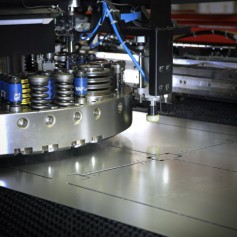

Bring your product ideas to Broki. Starting in the construction pahse we will look for a route to solving the problems you present taking efficiency, quality and costs into account.

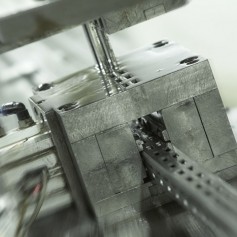

Our team in construction will support you with the most modern 3D-software, so that we can get a real impression of your products before production starts. Constructions are designed with our manufacturing environment in mind and we provide all machine data automatically as soon as the drawings are approved for the corresponding departs so that low cycle times are realised.